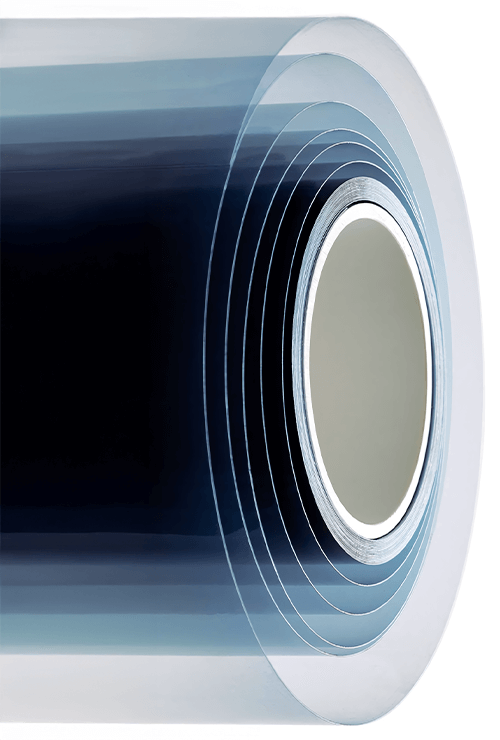

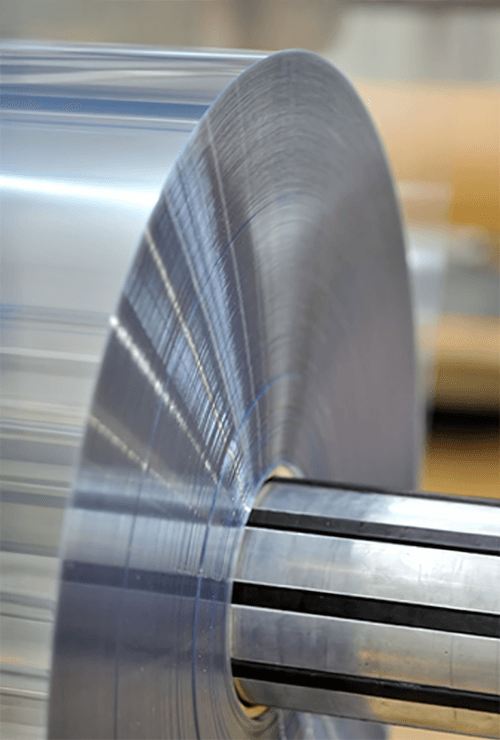

Our Rigid Foil Solutions for Food and Non-Food Production

MG Ambalaj offers co-extruded sheet solutions in the main plastic polymers: PET, PP, PS and PVC.

Our mono material rigid foils are the ideal solution for packaging fresh food, dairy products, blister packs for cosmetics and household products, as well as other industrial applications.

One of the main advantages of mono material packaging is its enhanced recycling capacity, which favours a circular economy, as well as requiring less energy consumption and optimising production processes.

We use anti-block, silicone coating and anti-fog materials in our food and non-food packaging produced with special formula options for thermoforming and FFS machines. We also offer high-transparency recycled products.

As your solution partner, MG Ambalaj can also provide you with laminated sheets such as APET//PE, APET/EVOH/PE, PVC//PE sheet, and barrier foil (barrier film) options like PP/EVOH/PP and PP/EVOH/PE.

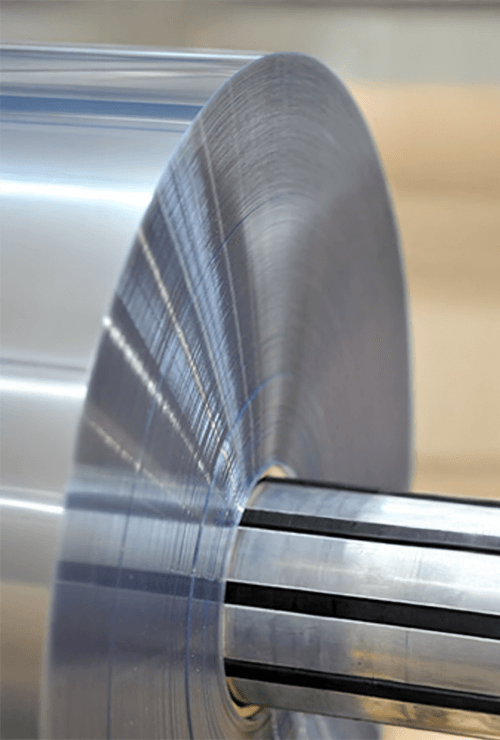

Our Rigid Foil Solutions for Food and Non-Food Production

MG Ambalaj offers co-extruded sheet solutions in the main plastic polymers: PET, PP, PS and PVC.

Our mono material rigid foils are the ideal solution for packaging fresh food, dairy products, blister packs for cosmetics and household products, as well as other industrial applications.

One of the main advantages of mono material packaging is its enhanced recycling capacity, which favours a circular economy, as well as requiring less energy consumption and optimising production processes.

We use anti-block, silicone coating and anti-fog materials in our food and non-food packaging produced with special formula options for thermoforming and FFS machines. We also offer high-transparency recycled products.

As your solution partner, MG Ambalaj can also provide you with laminated sheets such as APET//PE, APET/EVOH/PE, PVC//PE sheet, and barrier foil (barrier film) options like PP/EVOH/PP and PP/EVOH/PE.

APET FOIL

Polyethylene Terephthalate (PET) is one of the most widely used thermoplastics in the polyester family. It delivers ideal performance in food and non-food packaging, particularly for thermoforming and FFS applications.

Common Uses:

Plastic PET cups, trays, containers, food packaging, PET bottles, and PET sheets.

MG Ambalaj APET Solutions:

- APET Foil

- PET/PE Laminated Foil

- PET/EVOH/PE Barrier Foil

- Antifog PET Foil

- Metallised PET Foil

Antifog PET

Also known as “anti-mist,” this additive prevents fogging in clear packaging, ensuring the product inside remains visible ideal for cold chain use.

APET film stands out as one of the most dependable and multifunctional materials in rigid packaging, offering clarity, strength, and full recyclability. Its versatility extends across industries, from food and medical packaging to thermoformed consumer products. With advanced variants such as antifog, EVOH barrier, and RPET-based options, APET continues to evolve to meet performance, presentation, and sustainability expectations in one solution.

APET film stands out as one of the most dependable and multifunctional materials in rigid packaging, offering clarity, strength, and full recyclability. Its versatility extends across industries, from food and medical packaging to thermoformed consumer products. With advanced variants such as antifog, EVOH barrier, and RPET-based options, APET continues to evolve to meet performance, presentation, and sustainability expectations in one solution.

PVC FOIL

MG Ambalaj PVC Solutions:

- PVC Foil: Flexible and formable solution for general-purpose packaging and industrial applications.

- PVC/PE Laminated Foil: Combines PVC’s strength with PE’s sealing capabilities, offering secure and reliable packaging performance.

- PVC/EVOH/PE Barrier Foil: Integrates an EVOH barrier layer to block oxygen and moisture, ideal for extending the shelf life of sensitive products.

- Metallized PVC Foil: Enhanced with a thin metallic layer to provide increased protection and a refined aesthetic finish.

PVC FOIL

MG Ambalaj PVC Solutions:

- PVC Foil: Flexible and formable solution for general-purpose packaging and industrial applications.

- PVC/PE Laminated Foil: Combines PVC’s strength with PE’s sealing capabilities, offering secure and reliable packaging performance.

- PVC/EVOH/PE Barrier Foil: Integrates an EVOH barrier layer to block oxygen and moisture, ideal for extending the shelf life of sensitive products.

- Metallized PVC Foil: Enhanced with a thin metallic layer to provide increased protection and a refined aesthetic finish.

PVC foil remains a robust and flexible choice for a variety of packaging and industrial applications. With excellent clarity, formability, and chemical resistance, it serves the needs of sectors such as food, healthcare, construction, and advertising. MG Ambalaj’s PVC foil solutions reflect our commitment to quality, performance, and adaptable production technologies.

PVC foil remains a robust and flexible choice for a variety of packaging and industrial applications. With excellent clarity, formability, and chemical resistance, it serves the needs of sectors such as food, healthcare, construction, and advertising. MG Ambalaj’s PVC foil solutions reflect our commitment to quality, performance, and adaptable production technologies.

PP FOIL

Common Uses:

Plastic cups, cutlery, and heat-resistant food containers.

MG Ambalaj PP Solutions:

- PP Foil: Designed for general-purpose applications requiring a balance of strength and flexibility.

- PP/PE Laminated Foil: Combines the properties of PP with polyethylene (PE) to enhance sealing capabilities, suitable for airtight packaging needs.

- PP/EVOH/PE Barrier Foil: Incorporates Ethylene Vinyl Alcohol (EVOH) for superior barrier properties against gases and moisture, extending the shelf life of sensitive products.

PP FOIL

Common Uses:

Plastic cups, cutlery, and heat-resistant food containers.

MG Ambalaj PP Solutions:

- PP Foil: Designed for general-purpose applications requiring a balance of strength and flexibility.

- PP/PE Laminated Foil: Combines the properties of PP with polyethylene (PE) to enhance sealing capabilities, suitable for airtight packaging needs.

- PP/EVOH/PE Barrier Foil: Incorporates Ethylene Vinyl Alcohol (EVOH) for superior barrier properties against gases and moisture, extending the shelf life of sensitive products.

Polypropylene foil stands out as a multifaceted material offering a blend of lightweight, durability, and chemical resistance. Its adaptability across various industries underscores its significance in modern manufacturing and packaging solutions.

Polypropylene foil stands out as a multifaceted material offering a blend of lightweight, durability, and chemical resistance. Its adaptability across various industries underscores its significance in modern manufacturing and packaging solutions.

PS FOIL

Common Uses:

Yoghurt and ayran containers, breakfast packaging, disposable cutlery, PS cups, and trays.

MG Ambalaj PS Folio Solutions:

- Standard PS Foil: Suitable for general-purpose packaging requiring clarity and rigidity.

- PS/PE Laminated Foil: Combines PS’s structural benefits with polyethylene’s sealing capabilities, enhancing moisture resistance.

- PS/EVOH/PE Laminated Foil: Incorporates Ethylene Vinyl Alcohol (EVOH) for superior barrier properties against gases and moisture, extending product shelf life.

PS FOIL

Common Uses:

Yoghurt and ayran containers, breakfast packaging, disposable cutlery, PS cups, and trays.

MG Ambalaj PS Folio Solutions:

- Standard PS Foil: Suitable for general-purpose packaging requiring clarity and rigidity.

- PS/PE Laminated Foil: Combines PS’s structural benefits with polyethylene’s sealing capabilities, enhancing moisture resistance.

- PS/EVOH/PE Laminated Foil: Incorporates Ethylene Vinyl Alcohol (EVOH) for superior barrier properties against gases and moisture, extending product shelf life.

Polystyrene foil is widely used across multiple industries thanks to its lightweight structure, durability, and ease of processing. From food packaging to medical supplies, and from disposable items to protective casings for electronics, it serves a broad range of applications. At MG Ambalaj, we offer a variety of PS foil solutions tailored to sector-specific needs. With transparent, opaque, and PE-laminated options, we support your production processes while enhancing both the functionality and presentation of your products.

Polystyrene foil is widely used across multiple industries thanks to its lightweight structure, durability, and ease of processing. From food packaging to medical supplies, and from disposable items to protective casings for electronics, it serves a broad range of applications. At MG Ambalaj, we offer a variety of PS foil solutions tailored to sector-specific needs. With transparent, opaque, and PE-laminated options, we support your production processes while enhancing both the functionality and presentation of your products.

BARRIER FOIL

Why EVOH?

EVOH minimises oxygen permeability and preserves flavour, aroma, vitamins, and nutrients while forming a reliable barrier against external elements.

MAP Compatible:

Used in Modified Atmosphere Packaging (MAP), barrier films significantly extend shelf life by maintaining optimised gas mixtures.

Common Uses:

Meat, poultry, fish, delicatessen products, olives, pet food, coffee, sauces, filo dough, cooked pasta and rice, fresh produce, and ready meals.

MG Ambalaj PS Folio Solutions:

- PP/EVOH/PP

- PP/EVOH/PE

- PS/EVOH/PS

- PS/EVOH/PE

Why MG Ambalaj ?

Today MG Ambalaj is;

- Leading international and regional brands in Türkiye and all over the World.

- Manufacturing all types of packaging sheets for thermoforming products.

- Exporting more than 20 countries from USA and Europe to Africa and Middle East countries.

We Make a Difference with;

- Excellent clarity and perfect thermoforming ability.

- Consistency and Sustainability in Product Quality.

- Food Contact Products (FCMs) produced with Eco - Friendly materials with the structure of A/B/A

- For all your questions and requirements 24/7 Customer Service.

Operations & Logistics:

- CRM and Logistic Departments of MG Ambalaj are unified to strengthen and improve capabilities, effectiveness and the efficiency of the function. We do this with the aim and desire to improve our service.

24/7 Customer Service

-

As MG Ambalaj, we recognize the value of exemplary customer service and on-time delivery.

Flexibility and customer connectivity are our hallmarks.

A guarantee that you have teamed up with the right partner.

Why MG Ambalaj ?

Today MG Ambalaj is;

- Leading international and regional brands in Türkiye and all over the World.

- Manufacturing all types of packaging sheets for thermoforming products.

- Exporting more than 20 countries from USA and Europe to Africa and Middle East countries.

We Make a Difference with;

- Excellent clarity and perfect thermoforming ability.

- Consistency and Sustainability in Product Quality.

- Food Contact Products (FCMs) produced with Eco - Friendly materials with the structure of A/B/A

- For all your questions and requirements 24/7 Customer Service.

Operations & Logistics:

- CRM and Logistic Departments of MG Ambalaj are unified to strengthen and improve capabilities, effectiveness and the efficiency of the function. We do this with the aim and desire to improve our service.

24/7 Customer Service

-

As MG Ambalaj, we recognize the value of exemplary customer service and on-time delivery.

Flexibility and customer connectivity are our hallmarks.

A guarantee that you have teamed up with the right partner.

More than

400 domestic

and foreign

customers

Western Europe

UK

Spain

Italy

Nederlands

France

Scandinavia

Eastern Europe

Poland

Ukraine

Bulgaria

Romania

Serbia

Austria

Middle East / Africa

S. Arabia

U.A.E

Tunisia

Libya

Algeria

Iraq

America

USA

Chile

Brasil

Export

Destinations:

More than

20 countries

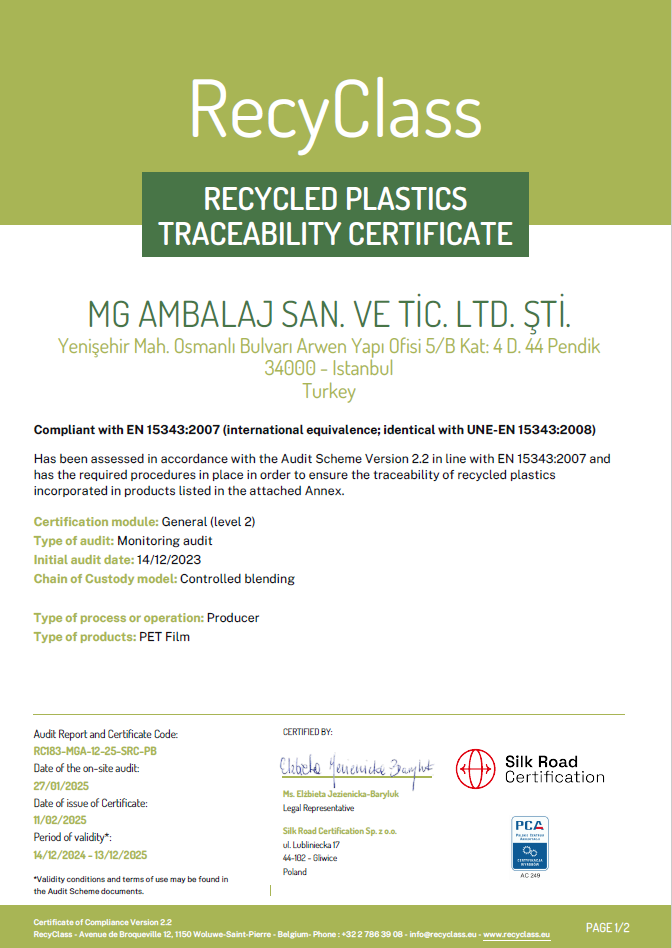

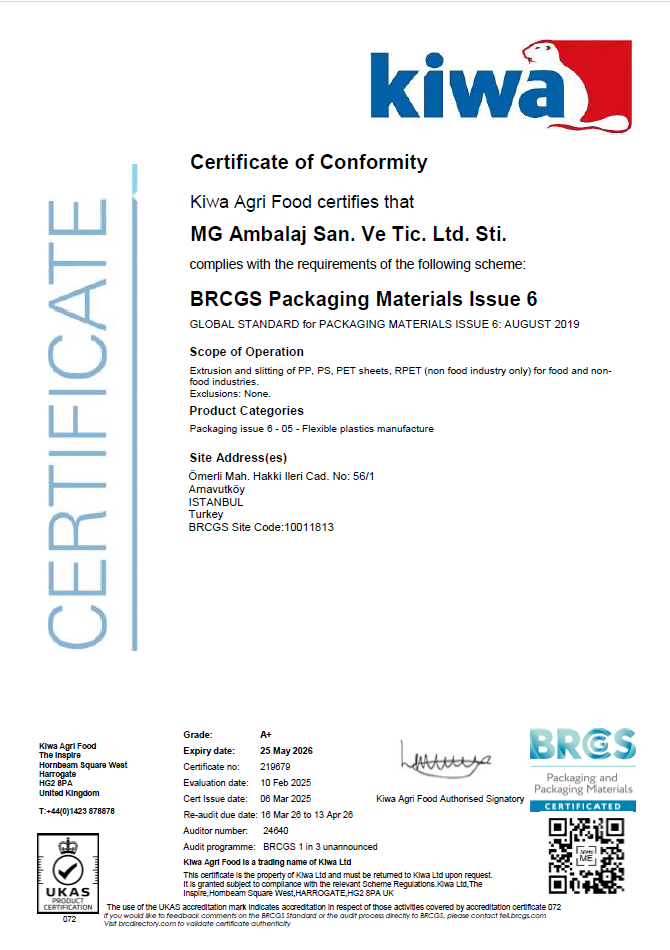

Our Certificates

At MG Ambalaj, every product produced in accordance with BRCGS quality standards, is controlled one by one at every stage of the process, from raw material input to product shipment. We develop and produce environmentally friendly packaging products with our policy based on environment and employee health and safety, our expert staff.